Rapid Deployment of Scalable DAQ System for MetTech Rotary Device Characterization

- Ajay MV

- Dec 30, 2024

- 2 min read

Updated: Oct 22

Challenge

A MedTech client needed to characterize rotary electromechanical systems (200–20,000 RPM) across four test benches but lacked in-house LabVIEW expertise. Their existing manual data collection caused:

Inconsistent measurements of torque, power, and RPM

No synchronization between electrical (power analyzers) and mechanical (torque sensors, encoders) data

Inability to scale testing for DUTs of varying sizes (10–500 kW)

Delays in generating ISO-compliant reports for R&D validation

Solution

We delivered a low-cost, modular NI CompactDAQ-based system within 3 weeks, featuring:

Hardware Integration

4x NI cDAQ-9188 chassis with modules:

NI 9237 (strain gauge for torque)

NI 9401 (encoder input for RPM)

NI 9265 (stepper motor control)

NI 9227 (3-phase electrical power measurement)

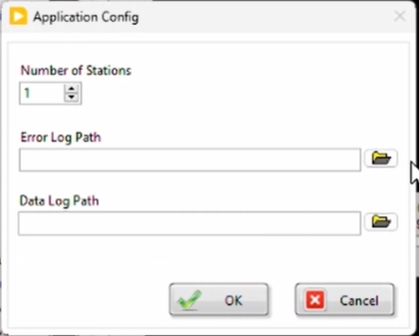

Custom LabVIEW Application

Key Features

Role-based user logins (Engineer vs. Technician)

Real-time plots with anomaly detection (e.g., torque-RPM mismatch)

Automated Excel/TDMS export matching the client’s master application schema

Error logging with timestamps and suggested debug actions (e.g., "Encoder signal lost: Check wiring on cDAQ1 Mod3")

Technical Differentiation

Our Approach | Typical Alternatives |

Unified TDMS data structure with DUT metadata (size, test ID) | Siloed CSV files per instrument |

<2 ms synchronization across 4 test benches using NI-TClk | Manual timestamp alignment |

Reusable framework: 80% code reuse for future DUT sizes | One-off scripts per project |

CompactDAQ reduced costs by 60% vs. PXI systems | Over-engineered setups |

Outcome

40% Faster Test Cycles: Automated data merging enabled cross-DUT analysis in Diadem (e.g., efficiency curves for 10–500 kW systems).

Zero Coding Required: Technicians now run tests via intuitive UI without LabVIEW skills.

Scalability Achieved: Client expanded to 8 test benches within 2 months using our template.

Error Resolution Time: Reduced from 4 hours to 15 minutes with embedded debug guides.

Supporting Documentation:

TDMS Data Schema Sample (Available upon NDA)

CompactDAQ Bill of Materials (Available upon NDA)

Comments